chariot iscrub 20 parts manual

Get the Chariot iScrub 20 parts manual for easy maintenance and repairs. Download your comprehensive guide now!

Welcome to the Chariot iScrub 20 Parts Manual, your comprehensive guide for understanding and maintaining your machine. This manual details key components, maintenance procedures, and troubleshooting tips to ensure optimal performance. Familiarize yourself with the content to maximize efficiency and safety.

Overview of the Chariot iScrub 20 Machine

The Chariot iScrub 20 is a battery-powered, stand-on, hard floor scrubber designed for commercial cleaning efficiency. It applies cleaning solution, scrubs the floor with brushes or pads, and vacuums soiled water into a recovery tank. With a 48-inch turning radius, it navigates tight spaces effortlessly. The machine features Aqua-Mizer technology to minimize water and solution consumption, making it eco-friendly. Its low operating noise enables daytime cleaning without disruptions. Designed for productivity, the iScrub 20 has a 20-inch cleaning path and uses dual brushes for effective cleaning. Tool-free brush and squeegee replacement simplify maintenance, reducing downtime; Eco-mode options optimize water and detergent use, supporting sustainable practices. Built for durability and ease of use, the Chariot iScrub 20 is a reliable choice for maintaining hard floors in commercial environments.

Key Features and Benefits of the Chariot iScrub 20

The Chariot iScrub 20 is a high-performance, battery-powered, stand-on scrubber designed for commercial cleaning. Its 20-inch cleaning path and dual-brush system ensure efficient floor coverage and thorough cleaning. The machine features Aqua-Mizer technology, which reduces water and solution consumption, making it eco-friendly and cost-effective. With a 48-inch turning radius, it excels in tight spaces, enhancing maneuverability. The low operating noise level allows for daytime cleaning without disrupting operations. Tool-free brush and squeegee replacement simplify maintenance, minimizing downtime. Eco-mode options optimize water and detergent use, supporting sustainable practices. The on-board charger provides convenience, and the intuitive control panel offers easy operation. These features combine to make the Chariot iScrub 20 a durable, efficient, and user-friendly solution for maintaining hard floors in commercial environments.

Operating Manual and Safety Guidelines

This section provides essential safety protocols and operational guidance for the Chariot iScrub 20. It outlines pre-operation checks, safe handling practices, and emergency procedures to ensure secure and effective machine operation.

Safety Procedures for Handling and Maintenance

Before servicing the Chariot iScrub 20, ensure the machine is on a level surface, powered off, and the battery disconnected. Wear protective gear, including gloves and safety glasses, to prevent injury. Regularly inspect brushes, squeegees, and vacuum components for wear or damage. Clear debris from the scrub deck and recovery tank to maintain proper function. When handling electrical components, avoid water exposure and ensure all connections are secure. For maintenance, refer to the manual for specific safety guidelines tailored to each task. Always follow lockout/tagout procedures to prevent accidental start-up. Properly ventilate the area during battery maintenance to avoid hydrogen gas buildup. Keep loose clothing and long hair tied back to avoid entanglement with moving parts. Ensure all tools are stored securely to prevent tripping hazards. By adhering to these safety protocols, you can ensure a safe working environment and prolong the machine’s operational life.

Step-by-Step Operational Instructions

Start by ensuring the machine is fully charged and all safety precautions are followed. Turn on the power switch and select the desired cleaning mode using the control panel. Adjust the solution flow rate based on the floor type and dirt level. Engage the brushes by pulling the traction handle and begin scrubbing in slow, overlapping passes. Use the squeegee to collect solution and debris, ensuring the recovery tank is empty before operation. Monitor the water and solution levels, refilling as needed. For tight spaces, utilize the machine’s 48-inch turning radius for maneuverability. After cleaning, return the machine to a level surface, power it off, and disconnect the battery. Regularly clean the brushes and squeegee to maintain performance. For routine maintenance, refer to the manual for specific procedures, such as brush replacement or vacuum motor checks. Proper operation ensures efficient cleaning and extends the machine’s lifespan.

Parts and Accessories for the Chariot iScrub 20

The Chariot iScrub 20 relies on genuine parts for optimal performance, with key components like brushes, squeegees, and vacuum motors ensuring efficient cleaning and longevity. Refer to the manual for details.

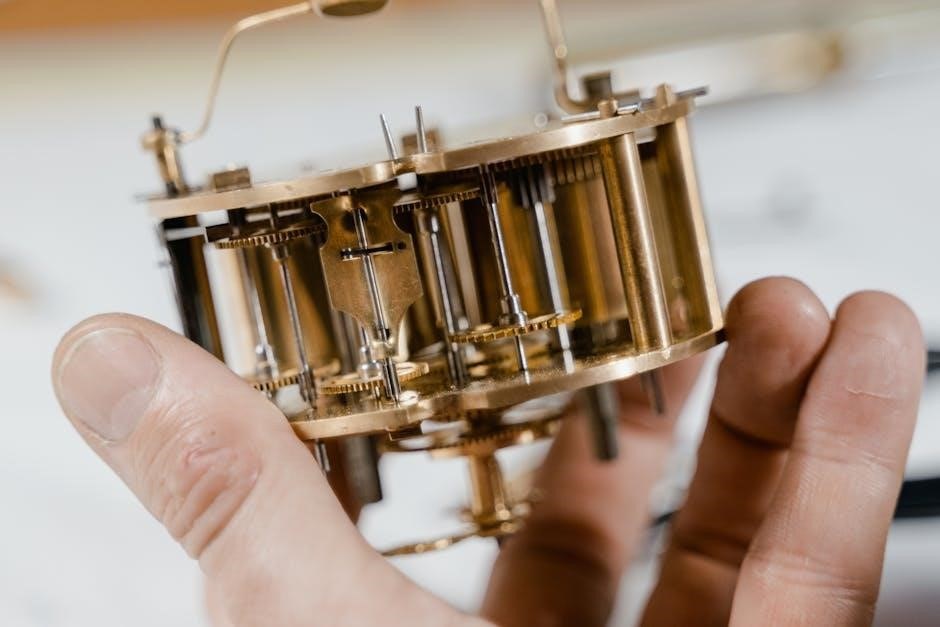

Popular Replacement Parts and Their Functions

Several key components are essential for maintaining the Chariot iScrub 20’s performance. The Hose Assembly (1.25 ID x 18.0, 4:1) ensures proper solution distribution, while the Ball Bearing (3/4 Bore Sphered) supports smooth machine operation. The Wheel (6.00 X 1.58, Gry W/Bearings) enhances mobility and durability; Additionally, the Switch (25A SPST 125-250V Snap) is crucial for controlling power functions. These parts are frequently replaced due to wear and tear, ensuring the machine continues to function efficiently. Regular inspection and replacement of these components are vital for optimal performance and longevity.

How to Identify and Order Spare Parts

To identify and order spare parts for your Chariot iScrub 20, refer to the detailed Parts List section in the manual. This section provides illustrations of assembled parts alongside corresponding part numbers, descriptions, and quantities. Locate the specific component you need by matching the part number or description. For accuracy, cross-reference the serial number of your machine, as some parts may vary based on the model or production date. Once identified, order parts through authorized dealers or the manufacturer’s online catalog using the provided part numbers. Ensure to use model-specific diagrams to avoid mismatches. Always verify the authenticity of the parts to guarantee compatibility and performance. This systematic approach ensures efficient maintenance and extends your machine’s lifespan. For further assistance, consult the HOW TO USE THIS MANUAL section or contact authorized support.

Troubleshooting and Maintenance Tips

Regularly inspect and clean the brushes and squeegee for optimal performance. Check for blockages in the vacuum and solution lines. Empty and rinse the recovery tank after each use to prevent debris buildup.

Common Issues and Solutions

One common issue with the Chariot iScrub 20 is the machine not picking up water effectively. This is often due to a clogged vacuum filter or debris in the squeegee. Clean or replace the filter and ensure the squeegee is free of blockages. Another issue is unusual noise during operation, which may indicate worn brushes or a malfunctioning vacuum motor. Inspect and replace brushes as needed, and check the motor for damage. If the machine isn’t dispensing cleaning solution, check the solution tank for proper connection and ensure the flow valve is open. Regular maintenance, such as cleaning the recovery tank and checking for blockages in the solution lines, can prevent many of these issues. Always refer to the manual for specific troubleshooting steps to ensure optimal performance and extend the machine’s lifespan.

Regular Maintenance Schedule for Optimal Performance

To ensure the Chariot iScrub 20 operates at its best, follow a regular maintenance schedule. Daily, inspect and clean the brushes, squeegee, and vacuum filter to remove debris. Check the solution tank and recovery tank for proper function and cleanliness. Weekly, lubricate moving parts like caster wheels and brush bearings. Every month, inspect the battery connections and water hoses for damage or leaks. Replace worn brushes or squeegee blades as needed. Annually, perform a thorough inspection of the vacuum motor and solution pump, and replace any worn-out components. Refer to the manual for specific part numbers and maintenance procedures. By adhering to this schedule, you can prevent unexpected downtime, reduce repair costs, and extend the lifespan of your machine. Always follow safety guidelines before performing any maintenance tasks.